Manufacturer/Exporter Of High Quality Blind Forged Flanges

Carbon, Alloy, Stainless Steel Blind Flanges

Used to stop the flow in a pipeline by using a solid disk, there is no opening contained in blind flanges to allow fluid to pass through. Instead, one places the blind flange between open flanges creating a block, thereby stopping the flow of a liquid through the pipeline. They typically have holes that are machined to match those of a what might be a connecting flange or valve that would be in that place. A blind flange is used commonly when a new valve needs to be installed or to shut down a pipeline that is no longer needed for use.

Our blind flanges are available with raised or RTJ faces and also with female threads. Blind flanges can be supplied with or without hub as per the customer requirements. We offer blind plate flanges manufactured at our facility to companies in various industries including shipbuilding, power generation, petrochemical plants, oil refineries, waste water treatment plants, paper mills, pharmaceutical plants and turnkey projects among others.

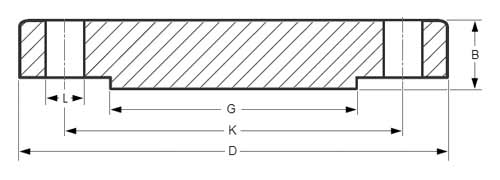

Dimensions Blind Flanges & Stud Bolts ASME B16.5

NPS 1/2

| CL | 150 | 300 | 600 | 900 | 1500 | 2500 | ||||||||||||

| DIA A | 30 | 38 | 38 | 38 | 38 | 43 | ||||||||||||

| DIA D | 90 | 95 | 95 | 120 | 120 | 135 | ||||||||||||

| DIA B |

|

|

|

|

|

|

||||||||||||

| DIA G | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 | ||||||||||||

| DIA K | 60.3 | 66.7 | 66.7 | 82.6 | 82.6 | 88.9 | ||||||||||||

| H |

|

|

|

|

|

|

||||||||||||

| No L | 4 | 4 | 4 | 4 | 4 | 4 | ||||||||||||

| DIA L | 15.9 | 15.9 | 15.9 | 22.2 | 22.2 | 22.2 |

Stud Bolts Diameter x Length

| DIA (IN) | 1/2 | 1/2 | 1/2 | 3/4 | 3/4 | 3/4 |

| Len mm | 55 | 65 | 75 | 110 | 110 | 120 |

Other Diameters

| NPS |

|

|

|

|

|

|

|

Notes:

• Dimensions are in millimeters unless otherwise indicated.

• The length of the Stud Bolt does not include the height of the chamfers (points).

Blind Flanges, BL Forged Flanges Production Range

Stainless Steel Plate/Forged Blind Flange (BL)

Alloy Steel, Carbon Steel Plate/ Forged Blind Flange (BL)

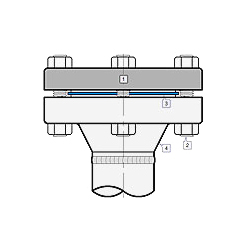

1-Blind flange | 2-Stud Bolt | 3-Gasket | 4-Other flange

ANSI B 16.5 Class 150

ANSI B 16.5 Class 300

ANSI B 16.5 Class 600

ANSI B 16.5 Class 900

ANSI B 16.5 Class 1500

ANSI B 16.5 Class 2500

Stainless Steel

ASTM A 182, A 240ASTM A 182, A 240

Grade

F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L, Duplex stainless steel UNS S31803, 2205, Super Duplex stainless steel UNS S32750

Carbon Steel

ASTM A 105, ASTM A 181

Alloy Steel

ASTM A 182, GR F1, F11, F22, F5, F9, F91

Nickel Alloys

Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22,C276

Copper Alloys

Copper, Brass & Gunmetal

Size

1/8" NB TO 48"NB.

Class

150#, 300#,400 #,600#,900#, 1500# & 2500 #.

Standard

ANSI ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN

DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

B.S

BS4504 , BS4504, BS1560, BS10

Advantage of Blind Flanges

• A much more cost efficient way to seal a pipe when doing repairs

• Blind flanges are convenient to install

• They can save a good amount of time and money

Because valves may be located extremely far, even miles from where the work needs to be done, a blind flange allows you to stop the flow of fluid much closer to the job site. Valves are also known to stick and are very expensive to replace depending on the type of valve being used. The less you have to mess with a valve the slimmer the chances you have of breaking it. So where a shutoff valve might be used, the placement of blind flanges may suffice.